Styrofoam Cutting Machine

Styrofoam cutting machines play a pivotal role in various industries, including construction, packaging, and arts and crafts. These machines provide an efficient and precise method for shaping and sizing styrofoam materials. The use of these machines has revolutionized the way businesses operate by significantly reducing manual labor, increasing productivity, and ensuring consistent quality of output. In the construction industry, for instance, styrofoam is often used as insulation material. With the help of a cutting machine, large blocks of styrofoam can be accurately cut into specific sizes to fit different building structures.

Styrofoam Cutting Machine in Various Industries

In the packaging industry, styrofoam cutting machine is indispensable tool that contribute to cost-effectiveness and efficiency. Styrofoam is widely used in this sector due to its lightweight yet sturdy nature which provides excellent protection for products during transit. A cutting machine allows for custom-sized packaging solutions that perfectly fit each product, minimizing waste and maximizing space utilization during shipping. This not only reduces costs but also promotes sustainability by reducing unnecessary waste.

Moreover, in the arts and crafts sector where precision is key to creating intricate designs and models, styrofoam cutting machines have proven invaluable. They allow artists to achieve complex shapes with ease while maintaining high levels of accuracy and consistency. This level of precision would be difficult to achieve manually or with less sophisticated equipment. Therefore, it’s clear that regardless of the industry they’re utilized in; styrofoam cutting machines offer significant benefits such as improved efficiency, cost savings, enhanced quality control, and increased productivity.

Key Features and Functions of Modern Styrofoam Cutting Machines

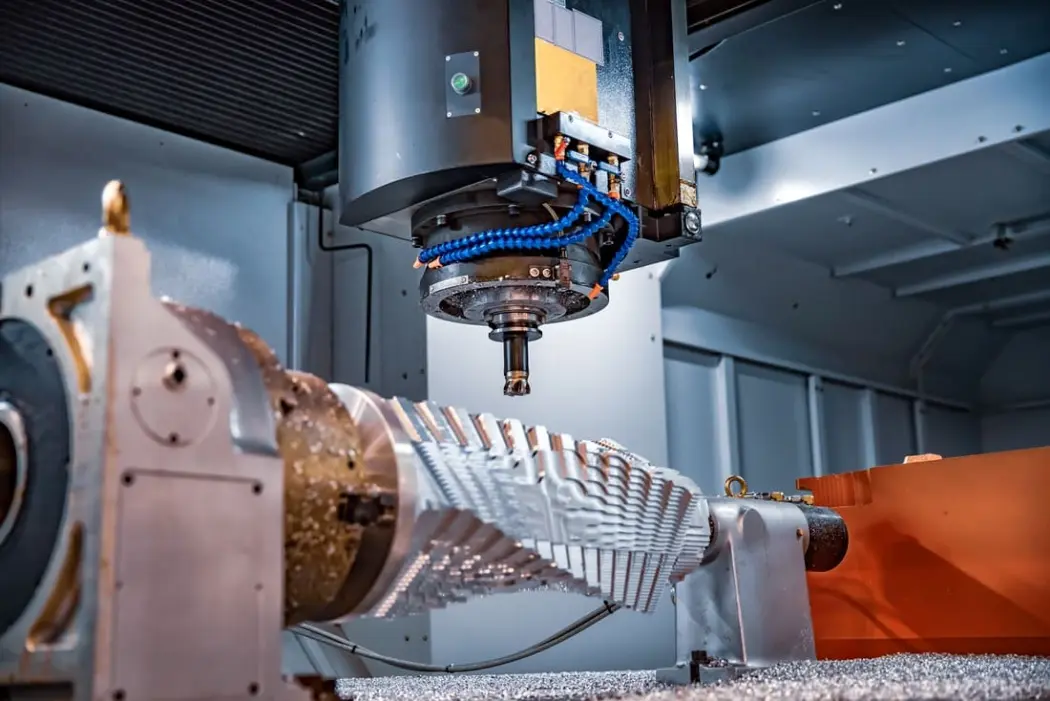

Modern styrofoam cutting machines are equipped with a plethora of features that make them indispensable in various industries. One of the key features is precision cutting, which ensures that the styrofoam is cut into exact dimensions as required. This feature is particularly beneficial for industries such as construction and packaging where accuracy is paramount. Additionally, these machines come with adjustable settings that allow users to control the speed and depth of the cuts, thereby providing flexibility for different types of projects.

Another significant function of modern styrofoam cutting machines is their ability to handle complex designs. With advanced software integration, these machines can interpret intricate patterns and execute them flawlessly on styrofoam. This capability opens up new possibilities for creative applications in fields like advertising, interior design, and event planning. Furthermore, many of these machines have automated functions which reduce manual labor and increase productivity. For instance, some models feature automatic feed systems or conveyor belts that continuously supply the machine with fresh material.

The safety features incorporated into modern styrofoam cutting machines should not be overlooked either. Most models come with built-in safety measures such as emergency stop buttons, protective guards around the cutting area, and heat protection to prevent overheating during prolonged use. These features ensure a safe working environment while also prolonging the lifespan of the machine itself. In conclusion, modern styrofoam cutting machines offer a combination of precision, versatility, automation and safety that significantly enhance their value in various industrial applications.

How to Choose the Right Styrofoam Cutting Machine for Your Business

Choosing the right styrofoam cutting machine for your business is a critical decision that can significantly impact your productivity and cost-effectiveness. The first factor to consider is the size and volume of styrofoam you will be handling. If your business deals with large quantities or sizes, investing in a heavy-duty machine with high cutting speed and precision would be beneficial. On the other hand, if you handle smaller volumes, a compact and more affordable model may suffice.

Another crucial aspect to consider is the type of cuts you need to make. Different machines offer various cutting capabilities such as straight, angled, or curved cuts. Some advanced models even provide 3D cutting options. Therefore, understanding your specific needs will help you select a machine that best suits your operations. Additionally, it’s essential to look at the machine’s ease of use and maintenance requirements. A user-friendly interface coupled with low maintenance needs can save time and reduce operational costs.

Lastly, don’t overlook the importance of durability and after-sales service when choosing a styrofoam cutting machine for your business. High-quality construction ensures longevity while excellent customer support can provide peace of mind in case of any technical issues or queries about the machine’s operation. By considering these factors carefully, you can choose a styrofoam cutting machine that not only meets your current needs but also accommodates future growth and technological advancements.

Tips and Techniques for Effective Styrofoam Cutting with a Machine

When it comes to effectively using a styrofoam cutting machine, there are several tips and techniques that can significantly enhance the quality of your work. First and foremost, it’s crucial to understand the type of styrofoam you’re working with. Different types of styrofoam have different densities and properties, which can affect how they should be cut. For instance, expanded polystyrene (EPS) is typically softer and easier to cut than extruded polystyrene (XPS), which is denser and more rigid.

Another important factor to consider is the blade used in your styrofoam cutting machine. A hot wire cutter is often recommended for its ability to melt through the foam smoothly, reducing the risk of chipping or breaking. However, if precision is key for your project, a CNC (Computer Numerical Control) machine might be a better choice as it allows for highly accurate cuts based on digital designs. Regardless of the type of blade you use, remember to keep it clean and sharp at all times to ensure optimal performance.

Lastly, don’t underestimate the importance of proper safety measures when operating a styrofoam cutting machine. Always wear protective gear such as gloves and safety glasses to protect yourself from potential hazards. Additionally, make sure your workspace is well-ventilated as cutting styrofoam can release harmful fumes. By following these tips and techniques, you’ll not only achieve better results but also maintain a safe working environment.

Enhancing Productivity and Cost-effectiveness with Styrofoam Cutting Machines

Styrofoam cutting machines are not just about precision and accuracy, they also play a significant role in enhancing productivity and cost-effectiveness. These machines can handle large volumes of styrofoam at a time, significantly reducing the amount of manual labor required. This increased efficiency translates into higher productivity levels for businesses. Moreover, the ability to produce consistent and high-quality cuts reduces waste, further contributing to cost savings.

The modern styrofoam cutting machine is designed with advanced features that allow for quick adjustments and easy operation. This means less time spent on setup and more time for production. Additionally, these machines require minimal maintenance which reduces downtime and associated costs. The combination of these factors results in a lower total cost of ownership, making it an economically viable solution for businesses of all sizes.

Furthermore, by automating the styrofoam cutting process, businesses can achieve greater consistency in their products. This not only improves the overall quality but also enhances customer satisfaction. In an increasingly competitive market environment, having reliable equipment like a styrofoam cutting machine can give businesses a significant edge over their competitors. Therefore, investing in such technology is not just about improving operational efficiency but also about driving business growth and profitability.

Future Innovations and Advancements in Styrofoam Cutting Machine Technology

As we look towards the future, it’s clear that technology will continue to play a pivotal role in the evolution of styrofoam cutting machines. Innovations are expected to focus on enhancing precision, speed, and efficiency while reducing energy consumption and waste. For instance, advancements in laser technology could lead to more precise cuts, minimizing material wastage and improving overall product quality. Additionally, the integration of AI and machine learning can optimize operational processes by predicting maintenance needs or identifying potential issues before they become problematic.

Another exciting area of development is the incorporation of IoT (Internet of Things) into these machines. This would allow for real-time monitoring and control over the cutting process from anywhere in the world. It could also facilitate seamless communication between different machines in a production line, leading to increased productivity and cost-effectiveness. Furthermore, with sustainability becoming a key concern across industries, we can expect future styrofoam cutting machines to be designed with eco-friendly features such as energy-efficient motors or recyclable components.

In conclusion, the future holds immense potential for innovations and advancements in styrofoam cutting machine technology. These developments not only promise to enhance operational efficiency but also contribute towards sustainable manufacturing practices. As businesses continue to adapt and evolve with these technological changes, it becomes increasingly important to stay informed about the latest trends and advancements in this field. By doing so, they can make strategic decisions that align with their business goals while also meeting their environmental responsibilities.

Autor: Materiał partnera